For our twins we wanted to build our own mobile so we could hang our Montessori mobiles. Being a fan of making a lot of our own toys, my wife made our own mobiles and I made the mobile/gym stand. Several people are requesting plans so I thought I would share them here as well.

Montessori DIY Mobile/Gym Stand

Materials

- Lumber (Red Oak/Poplar/Birch)

- Red Oak

- Poplar Dowel 1″

- 3/8″ Rope approx: 3-4 feet

- Sand Paper

- Glue

- Finish

- Beeswax & Olive Oil

- Danish Oil

- Polyurethane

| Quantity | Dimension | Purpose |

| 4 | 2” Wide x ¾” Thickness by 32” Long | Legs |

| 1 | 1″ Dowel by 32″ Long | Axle |

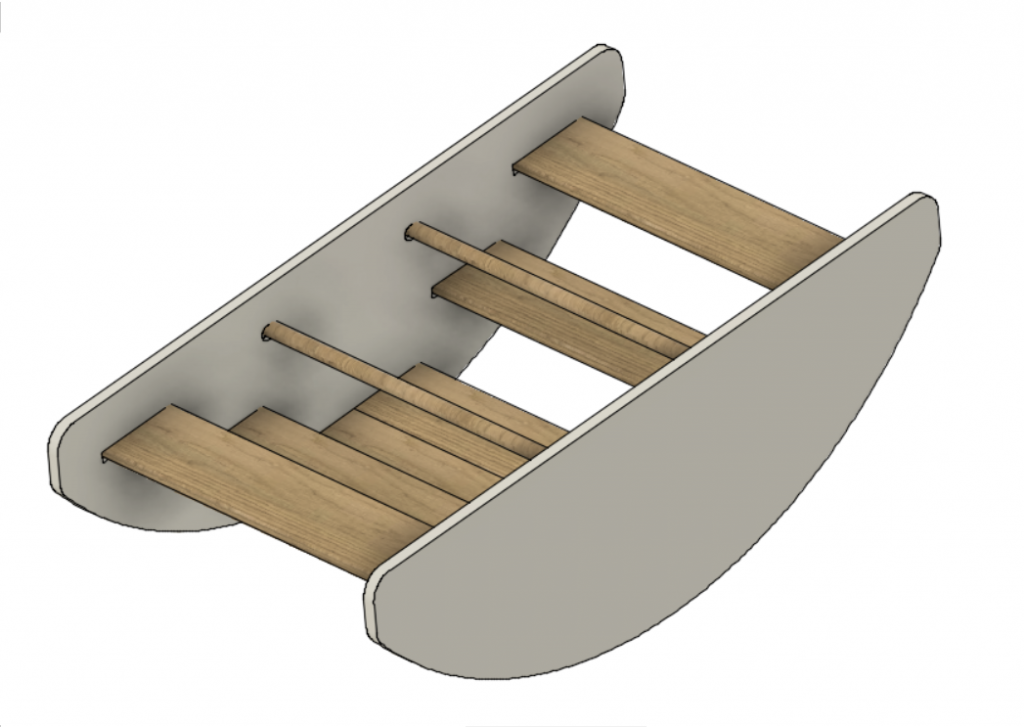

Building the mobile gym is very simple. You need four legs each out of 3/4″ lumber. I built mine out of red oak scrap I had leftover from our Montessori Spinning drums we build.

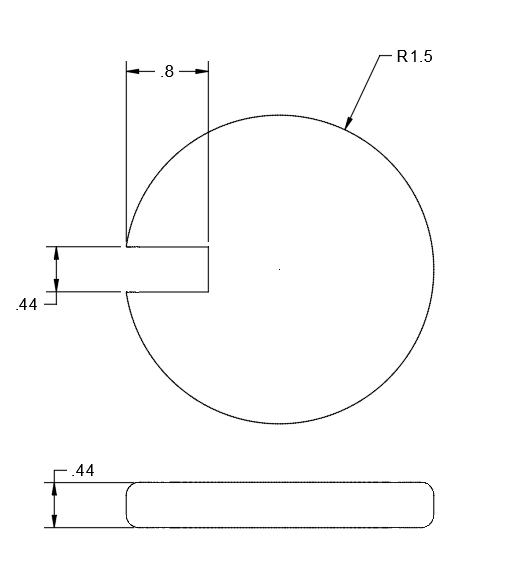

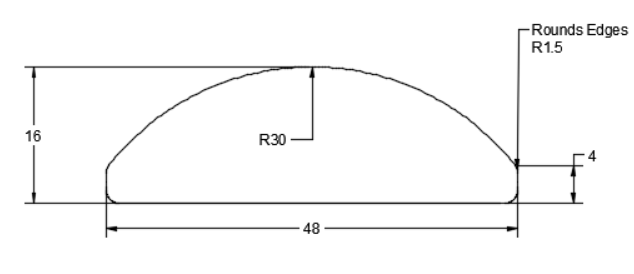

Each leg needs to be approximately 32″ in length and 2″ wide. Place a 1″ hole centered on one end of each leg exactly 1″ from the end of each board. This is important to make sure that the axles line up properly for a quality appearance.

Drill a smaller hole about 12″ from the top of each leg for adding a rope later in the process

Add a nice curve to each end of the boards and apply a nice smooth round-over to each edge.

Next cut your 1″ dowel to 32″ and assemble the finished product. Add some type of stops at the ends of the dowel to prevent the legs from moving along the dowel. I used smaller 1/4″ dowels. Sand and apply the finish of your choice.

The last step is to add a method to keep the legs from separating too far and to allow the gym to be adjusted to the right height for your needs.

We used rope through the lower holes made earlier to allow us to make the gym adjustable. Cut the rope and tie off knots when you find the right height and stability.

Your Mobile/Gym Stand is complete, enjoy!

Want to support us?

Our Own Shop

Our Etsy Shop

Tools Used

Some products displayed may earn us a commission. Learn More?

Recent Comments